OPTIFORM® MATERIALS

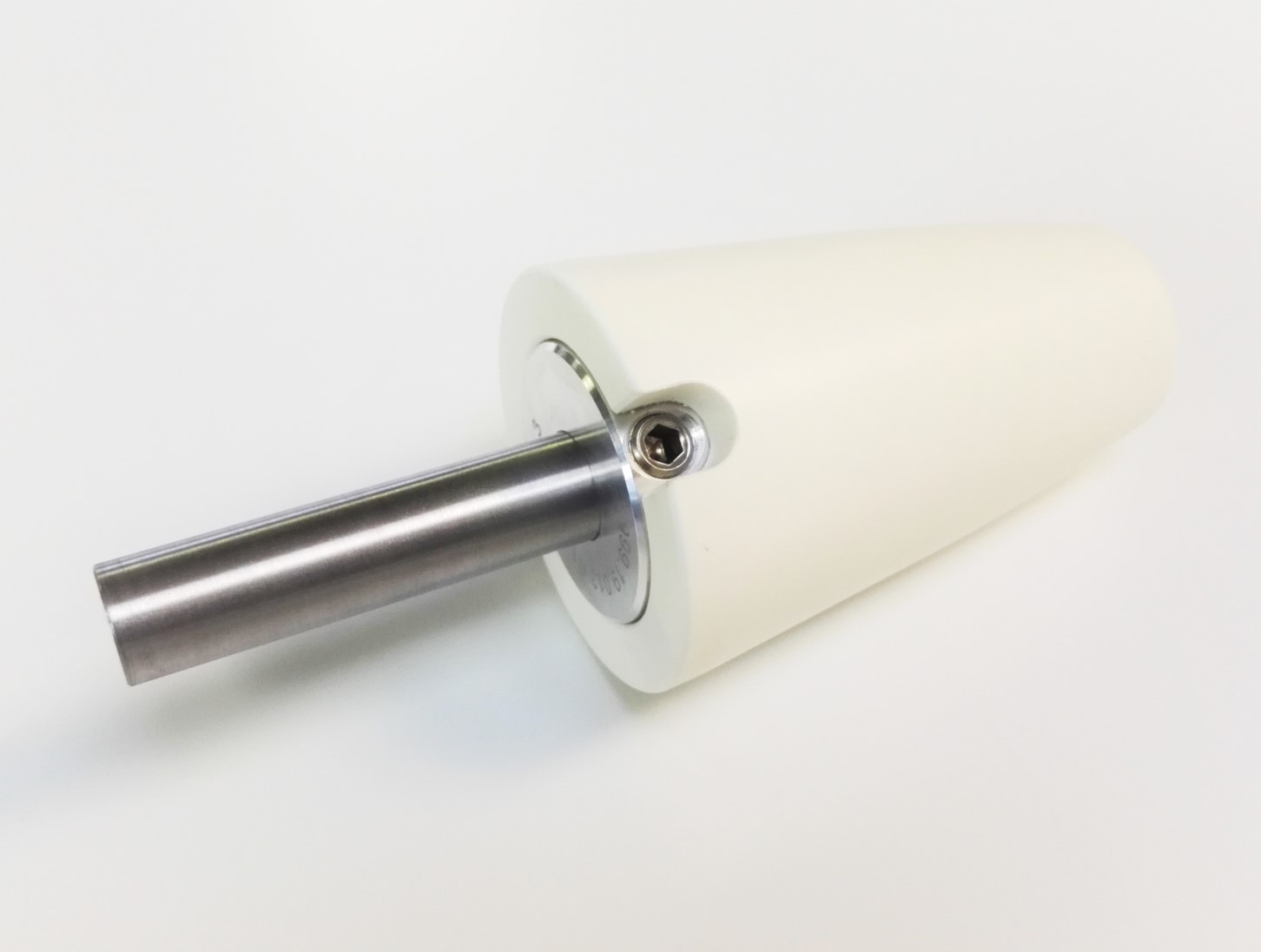

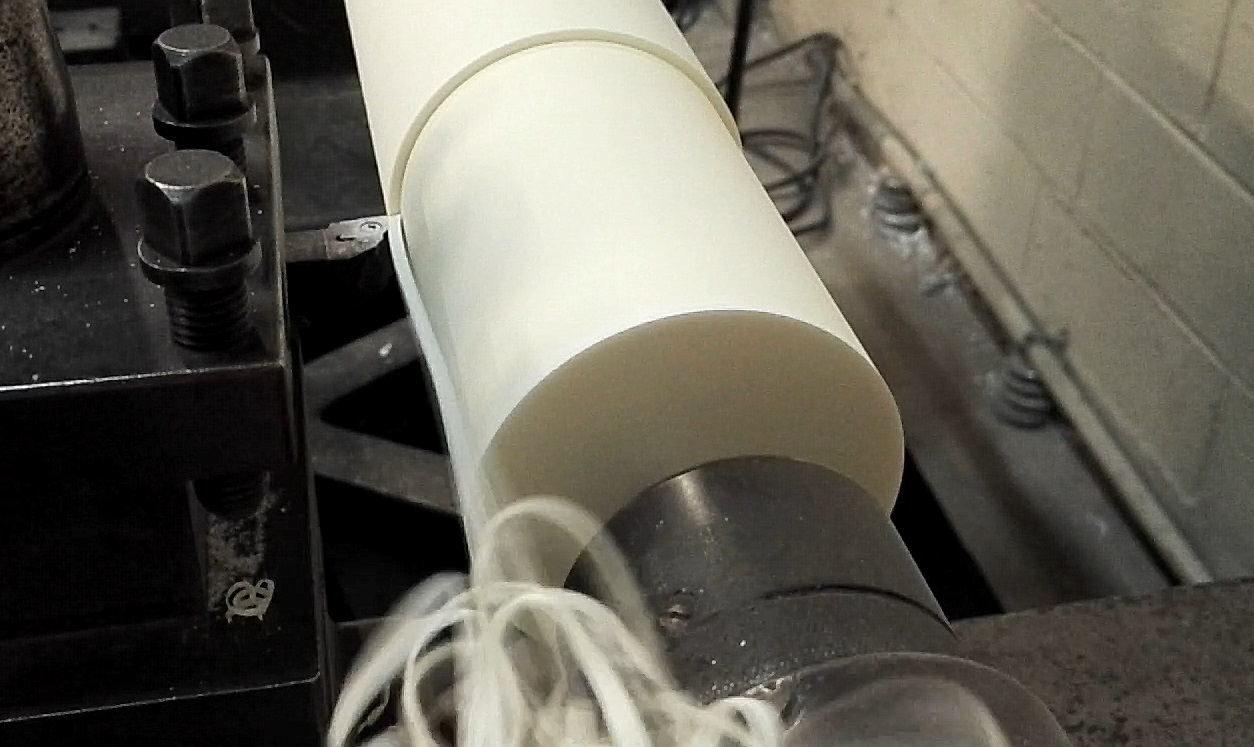

OptiForm® is a plug assist family of materials wich combines the toughness of engineering thermoplastics with the low thermal conductivity of a syntactic foam. Our plug assists will resist the chips and dings associated with production abuse while reducing mark-off and sticking of difficult to process polymers. Our material maintains the high thermal stability required to process today’s thermoformed polymers. In addition, OptiForm® Materials eliminates the machining difficulties of conventional syntactic foams. It is also the only range of plug assist materials in the market that is recyclable.

Discover our range of 4 different thermoplastic syntactic foam

F2X has been designed to replace old generation of epoxy syntactic that are very dusty to machine. F2X is much easy to thread, to put inserts and is dust free when machining. It will not crack compared to thermoset syntactic foam.

It is a cost effective plug assist materials for thermoforming PS, PVC, or PET.

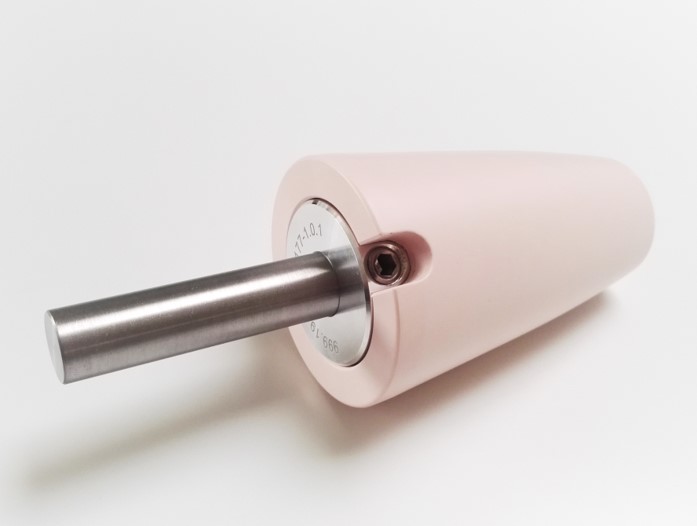

OptiForm SLX is the next generation of FLX replaced by a new copolymer thermoplastic material. SLX allows fine details machining with smooth surface finish.

SLX is a right choice for PET . It is widely use in multi-station thermoforming machine.

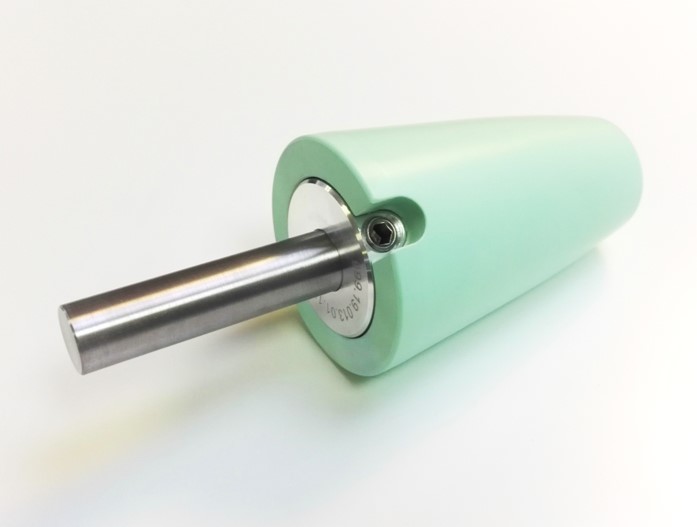

FXT is a new generation of thermoplastic syntactic with Teflon. The formulation has been designed to get the best material distribution for multilayer film.

FXT is the right choice for multilayer with PE top layer plastic films or for barrier films with EVOH. It is widely used in FFS thermoforming machine.

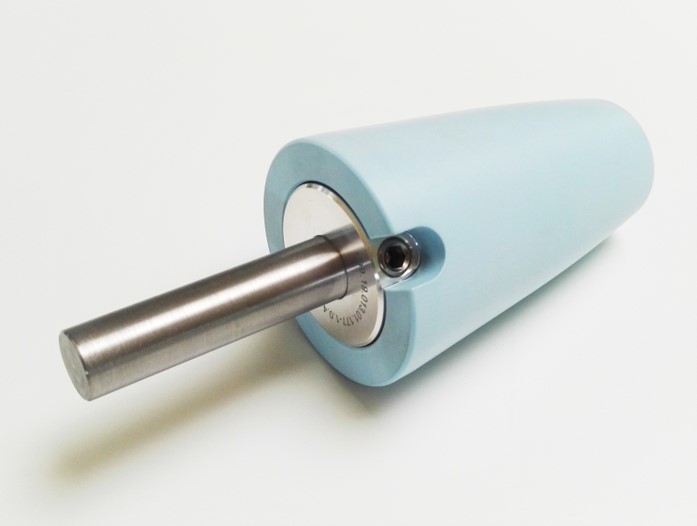

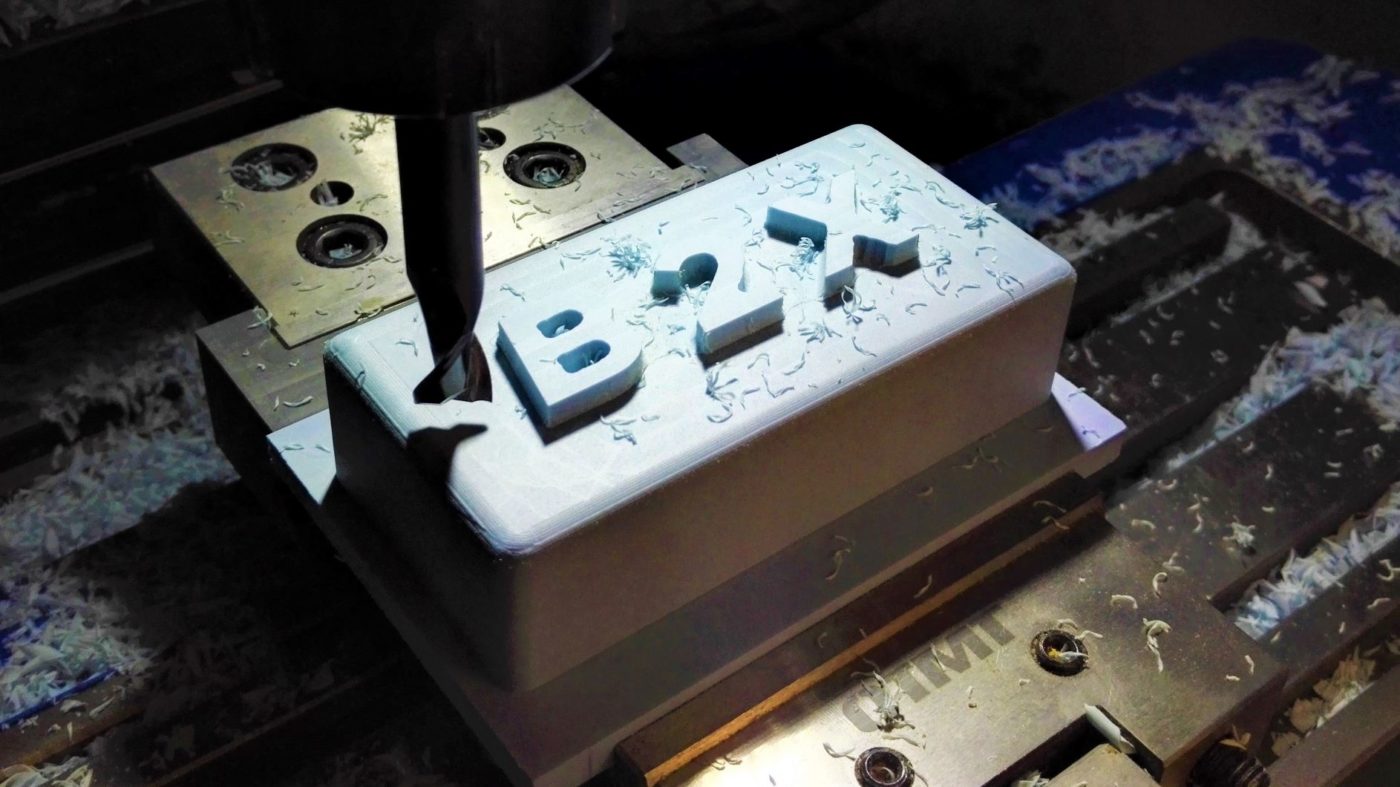

World’s number one choice in plug assist material due to the highest level of of toughness and durability.

B2X is the best choice for clarity, productivity, and long term use with PP, PET & PLA. It is mostly used in tilting machine for cups where the wear of plug should not be a break on the production.

| F2X | SLX | FXT | B2X | ||

|---|---|---|---|---|---|

| MACHINABILITY Moldmaker benefits | Dust Free | ||||

| Smoothness from machining | |||||

| Polishing | |||||

| Insert & Threading | |||||

| THERMOFORMING APPLICATION Thermoformer benefits | Material distribution | ||||

| Resistance to abuse | |||||

| Multilayer | |||||

| Deep draw | |||||

| Part Clarity | |||||

| Plug Durability |

OptiForm machining is NOT DUSTY. The thermoplastic elasticity enables you to get large or small chips according to the cutting parameters used by the machinist.

Deutsch

Deutsch Français

Français 中文 (中国)

中文 (中国) Español

Español Português

Português 한국어

한국어 Italiano

Italiano Türkçe

Türkçe العربية

العربية